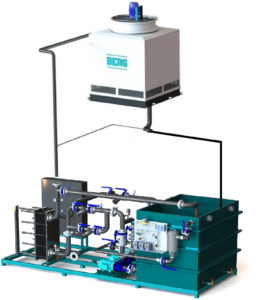

Cooling Tower Pump Tank Systems

For over 50 years, Berg Chilling Systems has been providing comprehensive pumping solutions that combine versatility, reliability, and efficiency to meet the specific needs of industrial applications.

With a wide selection of reservoir materials, including mild steel, stainless steel, and plastic, Berg provides reservoirs which are all securely mounted on a robust structural steel base. Additional long-term structural support is ensured through the incorporation of banding.

Berg's pumping systems range from single pump setups to multiple pump configurations, offering a multitude of options such as headers, detached pumping skids for convenient shipment and installation. The systems are equipped with central control panels that are PLC controlled, providing efficient and reliable operation.

Read more

Fully valved headers, variable frequency drives, and mounted auxiliaries such as chemical treatment and filters are available, enabling enhanced control and performance optimization. Expansion and closed mix tanks are also provided for closed-circuit systems that require additional capacity.

For larger tank setups, Berg offers multiple pumps configured on a double-ended tank set or modular detachable pumping, facilitating ease of shipping and installation.

A notable example is the Berg double pump tank system, which incorporates multiple pumps in conjunction with a baffled holding tank. The chiller pump, typically the smaller one, circulates water/glycol from the hot side of the tank to the chiller module(s) and back to the cold side of the tank. This pump ensures a consistent flow and pressure necessary for the cooling tower(s) to operate at maximum efficiency.

The process pump, usually the larger one, circulates chilled water from the cold side of the tank to the process machines and other users. This pump is specifically designed to match the varying flow and pressure requirements of the process load, without impacting the cooling tower's operation.