While standard air-cooled chillers work well for many industrial processes, some facilities have unique cooling requirements that demand a custom-engineered solution. A custom air-cooled chiller ensures your cooling system is perfectly matched to your process, space constraints, compliance needs, and operational environment.

Here are six clear signs that your operation would benefit from a custom industrial air-cooled chiller.

Processes with variable cooling loads, precise temperature tolerances, or multi-stage cooling needs often require custom chillers. Standard chillers may be over- or under-sized, resulting in inefficient operation, temperature swings, or equipment stress.

Example: In plastic extrusion, the cooling load can shift dramatically between production runs, requiring dynamic load management and precise temperature control, achievable only with custom-designed controls and capacity modulation. In 2022, Berg designed a custom air-cooled chiller for Cap-Thin Molds Inc., to meet precise cooling requirements for plastic cap and thin-wall molding.

Limited space, unusual building layouts, or retrofit projects may call for custom chillers designed with compact footprints, remote condensers, or flexible mounting options. Custom engineering allows chillers to fit into constrained mechanical rooms, be mounted outdoors or rooftops, or incorporate remote condensers to maximize floor space.

Example: In a food processing plant, production space is often at a premium, so the chiller may need to be located outside or in a dedicated mechanical room with non-standard dimensions. In 2022, Berg supplied a space-saving outdoor air-cooled chiller for Delmar Foods, which was designed to fit a limited footprint while delivering reliable process cooling.

Standard industrial chillers are typically rated for mild to moderate conditions. For facilities in coastal, high-humidity, or extreme temperature environments, chillers built with specialized materials and coatings to withstand tough conditions can ensure reliability and longevity.

Example: A chemical processing facility in a coastal region may require marine-grade coatings, corrosion-resistant materials, and climate-specific controls to ensure reliable long-term performance. In 2019, Berg engineered a custom electronics cooling solution for Elta Systems Ltd., designed for deployment on a military vessel operating in harsh marine environments.

Industries such as pharmaceuticals, food & beverage, and energy processing must meet strict regulatory standards for temperature control, refrigerants, and operational safety. Custom chillers can be built to support compliance and audit-readiness.

Example: A pharmaceutical plant may need precise GMP-compliant temperature control, validated performance documentation, and redundant systems for critical processes. In 2022, Berg supplied a low-temperature air-cooled chiller to BioVectra Inc., designed to meet stringent pharmaceutical process requirements and validated temperature performance.

In many industrial facilities, cooling systems are just one part of a larger, interconnected process. Custom chillers can be designed to seamlessly integrate with existing automation systems, SCADA platforms, and remote monitoring solutions.

Example: Berg provided a custom air-cooled chiller for GTUIT's modular gas treatment system, ensuring seamless integration with process controls for remote wellhead operations.

For energy-intensive industries, custom chillers can incorporate features like variable frequency drives (VFDs), heat recovery, and free cooling, helping facilities meet energy efficiency and carbon reduction goals.

Example: In a dairy processing facility, waste heat from the chiller could be repurposed to preheat water for CIP (clean-in-place) systems. In 2022, Berg an energy-efficient outdoor air-cooled chiller for a leading dairy products corporation, helping them reduce energy use while maintaining reliable cooling.

The right custom chiller does more than solve immediate cooling challenges. It also future-proofs your operation, enhancing:

To see how Berg’s custom engineering expertise supports industries from plastics and food production to natural gas processing and pharmaceuticals, explore our Project Spotlights.

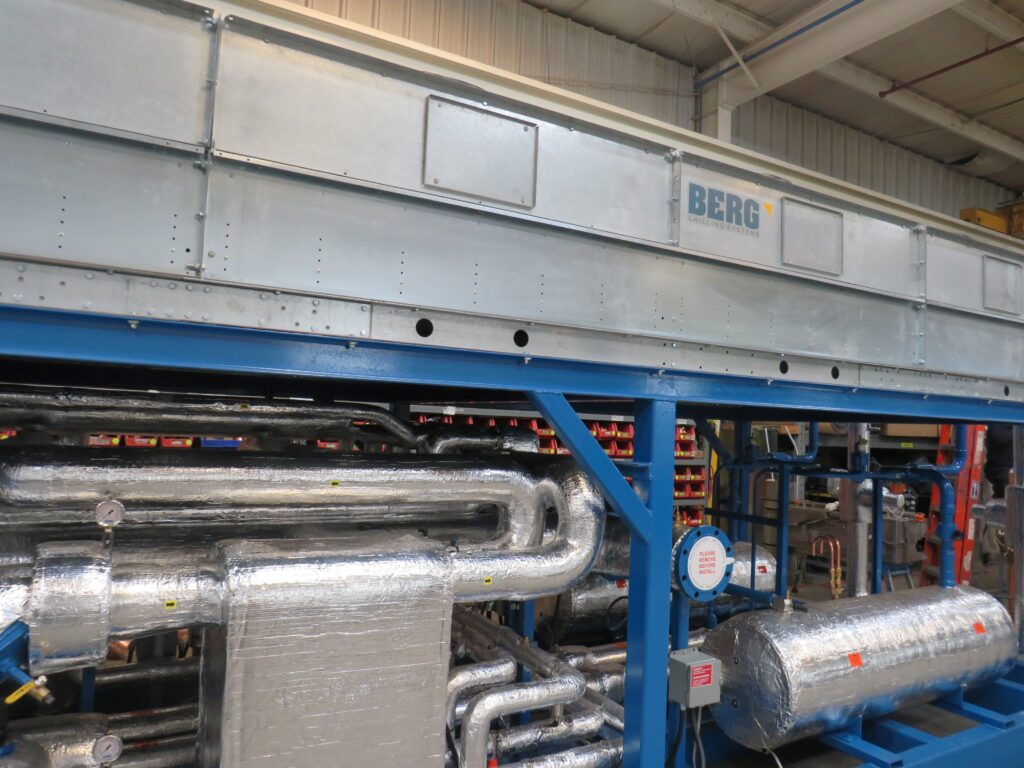

At Berg Chilling Systems, we specialize in designing and manufacturing custom-engineered air-cooled chillers for a wide range of industries, including food & beverage, plastics, pharmaceuticals, energy, and beyond. We work closely with each client to:

Contact us today to discuss your specific cooling challenges and discover how our custom-engineered solutions can improve your process efficiency.