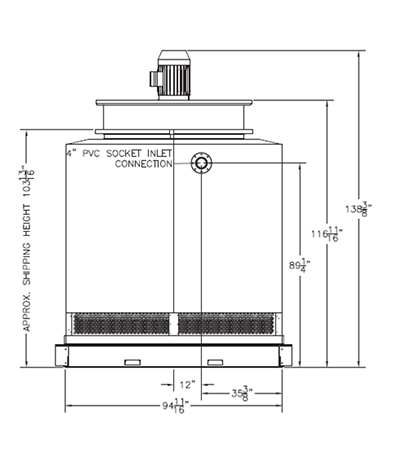

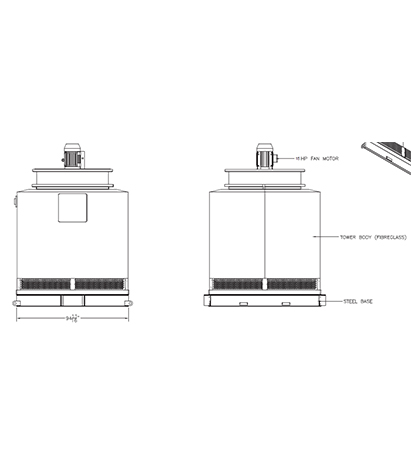

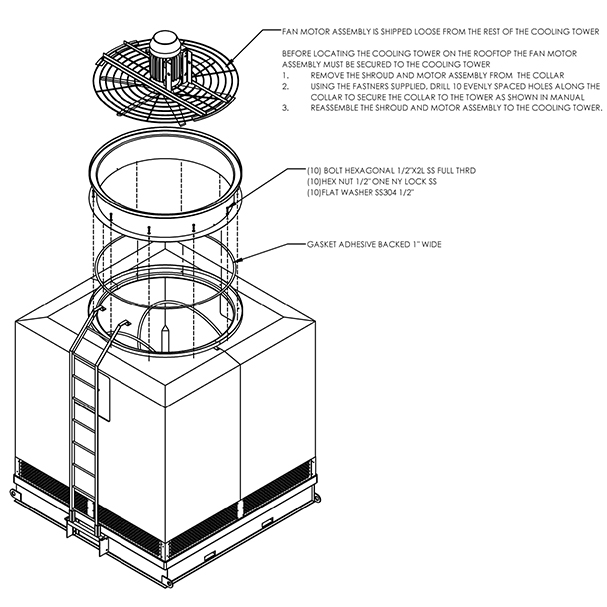

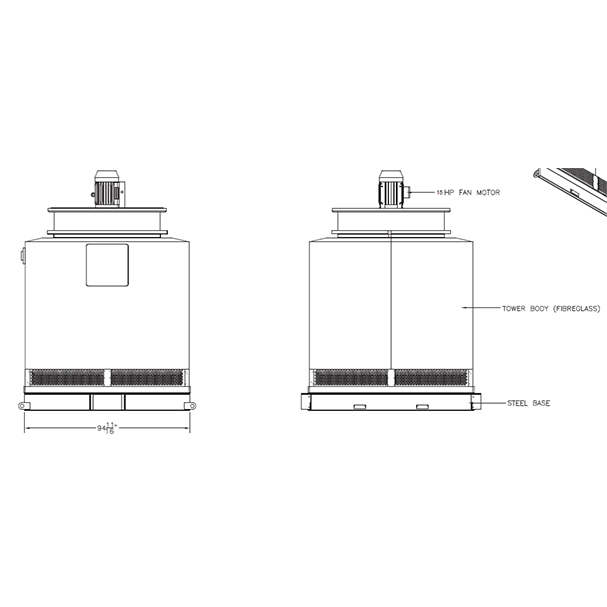

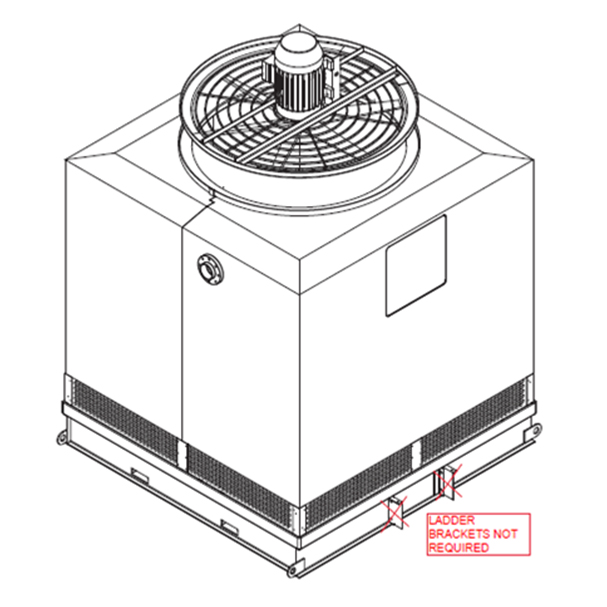

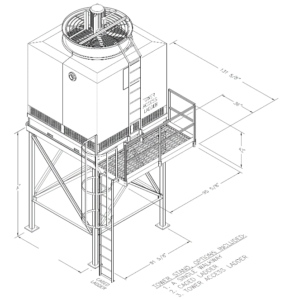

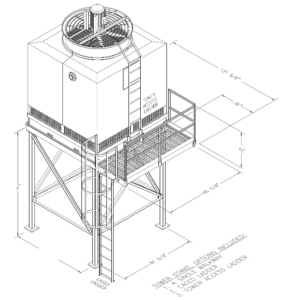

Berg’s line of fiberglass industrial cooling towers are manufactured of extra thick fiberglass and premium quality components to provide years of trouble-free, low maintenance performance.

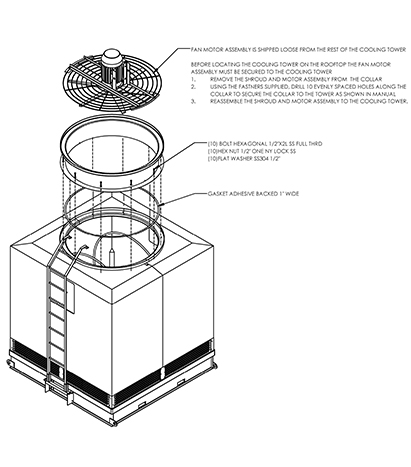

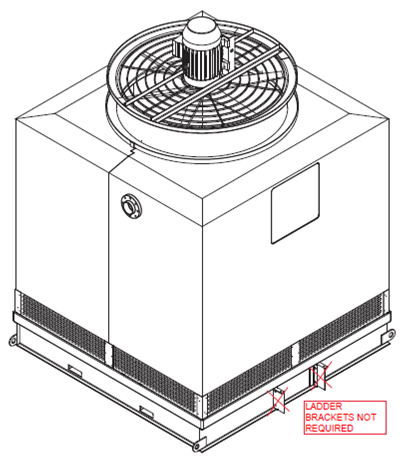

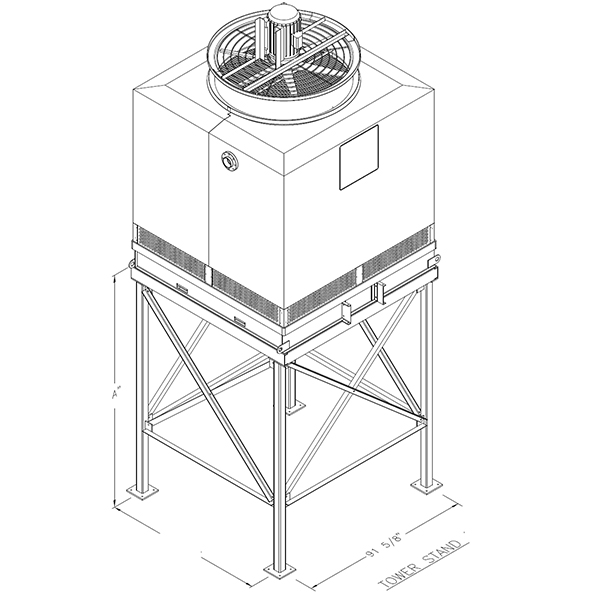

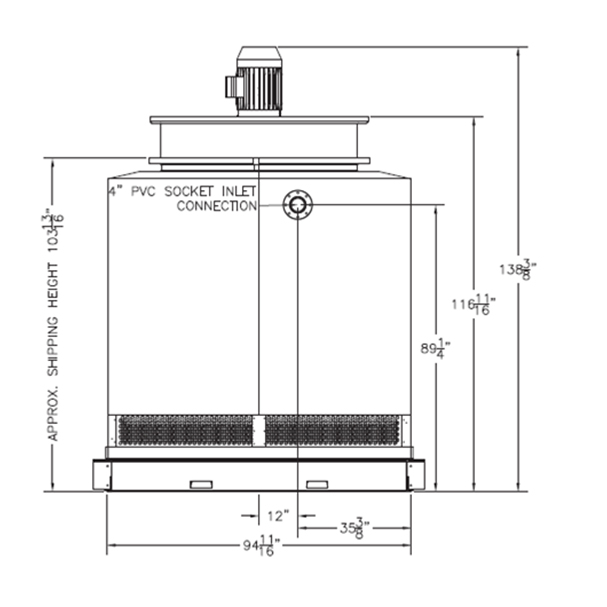

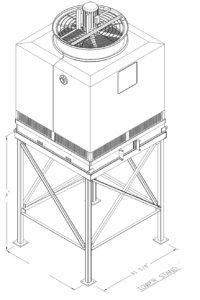

They feature a host of standard features and are supplied fully assembled on a structural steel integral base for easier installation and hook-up.