Safety is a key concern for industrial refrigeration facilities. Regardless the size of your chilling system, the constantly fluctuating hot and cold temperatures flowing through chiller pipes creates intense pressurization. Left unchecked, the intensity of this pressure may not only significantly weaken valve sealants and harm your chilling system, it could become a potentially fatal hazard for your employees.

Keeping your chilling equipment parts in top working condition is an utmost priority.

The first step to ensuring refrigeration safety is to confirm that your chilling equipment parts have been built by American Society of Mechanical Engineers (ASME) certified manufacturer. ASME code requires that pressure relief valves are constructed in such a way that makes adjusting the relief settings without breaking the seal impossible. To ensure that your chilling system has been properly built look for the following identification markings:

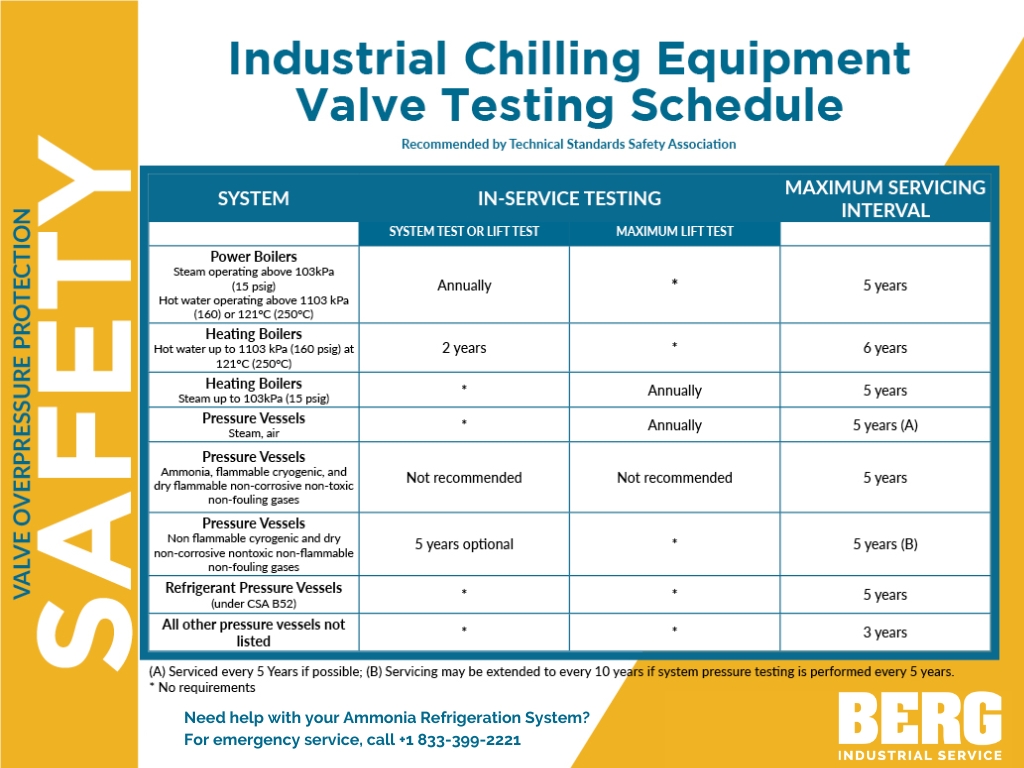

Chilling system pressure equipment must be serviced at regular intervals for safe industrial refrigeration operation. Download our Valve Testing Chart for recommended schedule maintenance times. Servicing industrial refrigeration pressure vessels using ammonia or other non-toxic gases should be professionally serviced at least every five years as should other refrigerant pressure vessels under CSA B52. Servicing systems with corrosive or liquid substances may require shorter intervals if valves have lifted to relieve pressure. See the chart for a full listing of recommended service intervals.

Servicing pressure relief valves is dangerous. These chilling parts must be inspected and serviced by an industrial refrigeration professional. To verify that your technician meets industry standards, confirm that they certification from the Technical Standards Safety Association (TSSA) or VR stamp certification from the National Board of Boiler and Pressure Vessel Inspectors is valid and up to date. Armed with an accurate knowledge of the chilling system’s manufacturing as well as a detailed account of its service history, these professionals should be equipped with what it takes to provide these typical service operations:

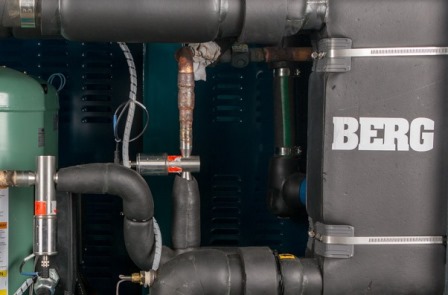

Berg Industrial Service provides chiller maintenance services to industrial refrigeration facilities of all types. Our licensed registered technicians not only meet industry standards, we exceed them. Through careful communications and fact finding as well as minute attention to detail we’re able to identify, repair, or replace valves and any other overpressure concerns before they become a safety hazard.

Contact us today to ensure your chilling system parts are kept in top shape and your equipment stands the test of time.