A compressor is a vital part of an industrial chilling system. It compresses the gas and moves the refrigerant around the chilling system. As long as the compressor is running it will impose a force on the refrigerant to continue circulating around the loop and continue removing heat from one location and rejecting it into another area.

If a compressor is not functioning correctly, due to improper commissioning or wear and tear it can be costly to your business and pose risks.

Most of these dangers can be avoided by having a professional commission your refrigeration system compressor and by performing regular maintenance tasks.

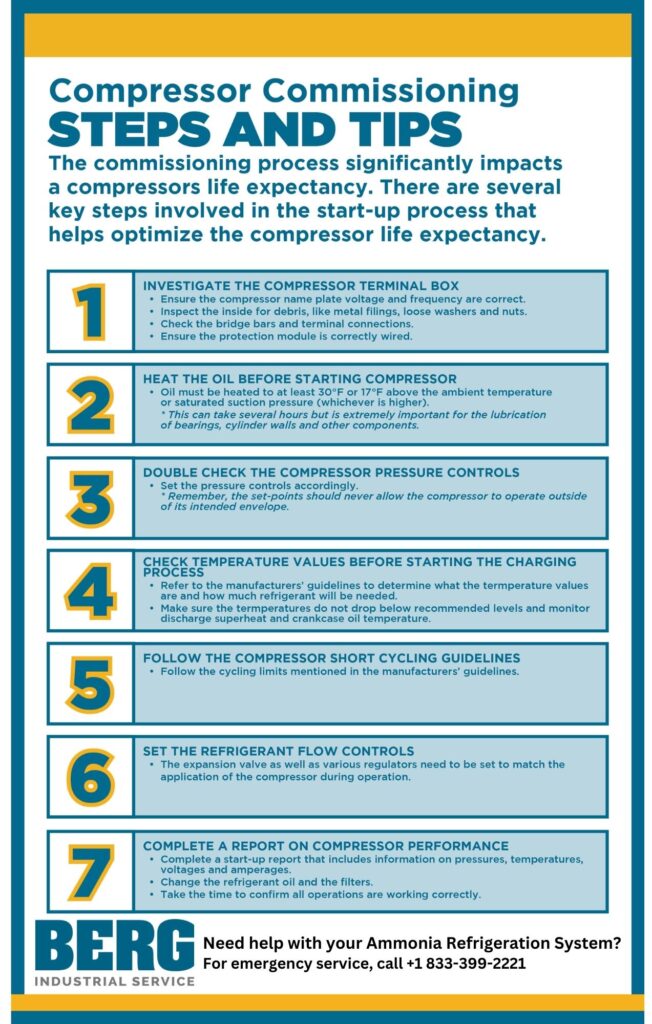

The commissioning process significantly impacts a compressors life expectancy. There are several key steps involved in the start-up process that help optimize the compressor life expectancy.

The first step should always be to check out the terminal box. From the terminal box you can ensure that the compressor name plate voltage and frequency are correct for the application. Then you can remove the cove and inspect the inside for debris, like metal filling, loose washers and nuts. You will also want to check the bridge bars and terminal connections. The last thing to check on the terminal box is the protection module. Ensure that it is correctly wired so that in the event of the starter overheating the compressor will shut down.

Before starting the compressor oil must be heated to at least 30°F or 17°F above the ambient temperature or saturated suction pressure (whichever is higher). This can take several hours but is extremely important for the lubrication of bearings, cylinder walls and other components. Cold oil increases the amount of refrigerant which is absorbed, decreasing the viscosity and ability to lubricate.

Do not assume that the pressures are pre-set from the factory. Set the pressure controls accordingly, remembering that the set-points should never allow the compressor to operate outside of its intended envelope.

Before the charging process begins, you should refer to the manufacturers’ guidelines to determine what the temperature values are and how much refrigerant will be needed. This way you can make sure the temperatures do not drop below recommended levels and monitor discharge superheat and crankcase oil temperature.

Check and follow the cycling limits mentioned in the Manufacturers’ guidelines. When a compressor is bring brought online, because it contains partial refrigerant charge it is possible for a short cycling of the low-pressure control to take place. The compressor frequently draws the stating current as a result of motor heat accumulation.

The expansion valve as well as various regulators need to be set to match the application of the compressor during operation.

Complete a start-up report that includes information on pressures, temperatures, voltages and amperages. Change the refrigerant oil and the filters. Take the time to confirm all operations are working correctly.

Download this infographic to help you remember the important steps and tips involved with compressor commissioning.

Technicians should complete maintenance tasks throughout the year and annually on industrial refrigeration systems. This will help keep an industrial refrigerated system running at peak performance and cut down on wear and tear costs. Here is a useful mechanical refrigeration checklist of monthly and annual maintenance tasks.

At Berg, our professional and highly trained technicians have experience commissioning compressors, overhauling compressors and repairing compressors of a variety of brands. We understand how vital your refrigeration system is to your business, that’s why our service team is on call 24 hours a day!

Contact Berg Industrial Service to get started!