With warmer weather here, it’s the perfect time to check off your condenser and evaporator fan coil maintenance from your refrigeration maintenance to do list. Dirty HVAC and refrigeration evaporator coils and condenser coils can reduce system efficiency by up to 70%! This dramatically increases operating costs and reduces the life expectancy of your refrigeration system.

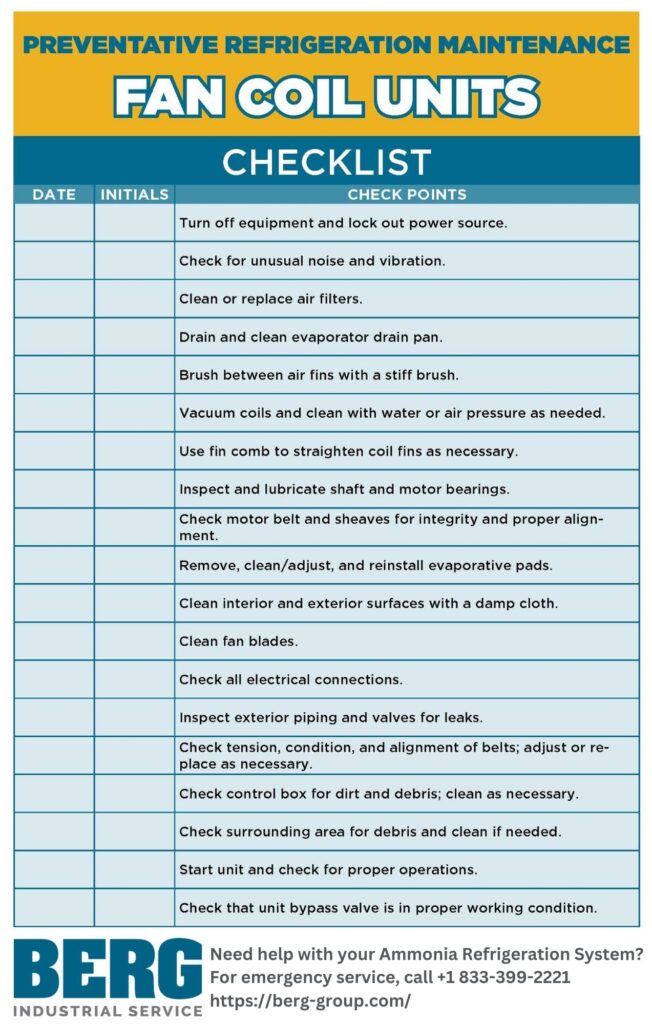

As with all components of industrial refrigeration systems, properly caring for and maintaining the fan coil units of your system can heavily impact how your chiller performs overall. Taking the time to schedule, create, conduct and log a thorough fan coil maintenance plan will maximize the life and performance of your refrigeration system.

Fan coil units are made up of three key components: the motor, the filter, and the coil itself. Carefully inspecting each area of the unit and making necessary repairs or replacements can be a tedious job; yet, how each part functions can significantly impact the others.

Forget to check the filter? You will soon find the motor straining beneath the weight of the dust and debris build-up. Fail to replace a fuse with the exact size, type, and voltage needed? You could find your whole system shutting down.

When it comes to the food and beverage industry and ice rink facilities, chancing even an hour of down time is a risk most aren’t willing to take.

Because each fan coil unit operates in its own unique environment, there is not a set scheduling recommendation for the refrigeration industry. Most refrigeration systems do not operate in dusty or dirty environments that require frequent inspections, so a standard bi-annual inspection may be sufficient.

However, at Berg Industrial Service we recommend performing refrigeration maintenance on your fan coil unit during the Spring. This is when warmer weather kicks in and your refrigeration system starts to work harder. By completing fan coil maintenance, you are able to increase your refrigeration system’s efficiency and save on operating costs.

To determine the optimal maintenance schedule for your system we advise you contact a refrigeration maintenance technician.

Is it just a matter of routinely checking the coils to make sure nothing has lodged itself between the fins and brushing away the accumulated dust? As this article points out, taking the extra maintenance steps to tend to your unit is well worth the extra effort.

If someone on your maintenance staff has extensive HVAC experience, they may be able to perform a visual inspection and fill out the refrigeration maintenance report. Once you have the report, it is in your best interest to call a licensed trade certified technician to schedule an air handler maintenance service call.

Berg professional can examine, clean, lubricate your fan coil unit, test the controls, and ensure proper function, without having to remove the coil. Berg technicians use an innovative portable coil cleaning system that can clean coils in place. It can handle virtually any coil cleaning need, from indoor evaporator coils to walk-ins and cold rooms, to 8” thick condenser coils and everything in between.

If the motor, coils, sheaths, or other parts need servicing or replacing, Berg can repair or replace the items according to manufacturer recommendations and restore your chiller unit to maximum operating efficiency.

Contact us to learn more about how preventive maintenance can save you time and money or to schedule a service call.