Increased particulate matter in the summer months means your industrial air chiller needs to filter and handle greater levels of pollen and dust in addition to higher temperatures. These factors contribute to an increased workload on your chilling system, lowering efficiency and increasing costs. Spring is a great time for plant managers and ice rink technicians to think about annual chiller maintenance tasks and ways to improve their industrial refrigeration system’s efficiency.

One way to cut down on operating costs and increase efficiency is to install a VFD (Variable Frequency Drive). This will allow you to vary control on lock in the system’s head pressure, which will prevent compressors from starting and stopping frequently and allow the refrigeration system’s air unit evaporator fans to operate more quietly and efficiently. To summarize, soft starting reduces electrical costs and VFDs are important to load capacity.

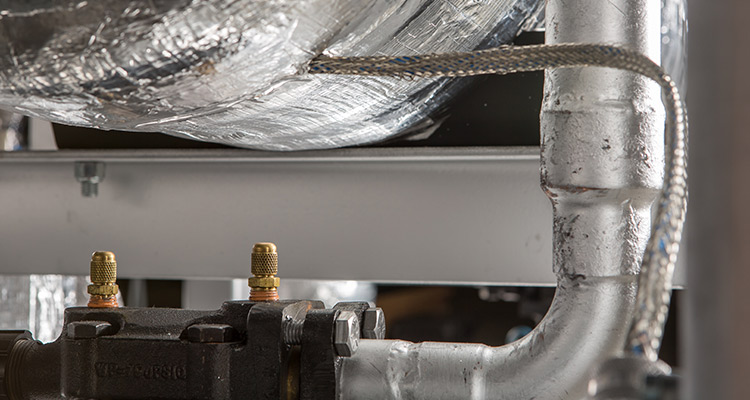

Draining refrigerant oil is an important maintenance task which if forgotten can lead to higher operating costs. When refrigerant oil is not drained, it causes poor temperature and heat transfer. These factors force the chilling system to work harder overall, and if unresolved can cause the entire system to shut down.

Draining refrigerant oil should only be done by professionals who have been trained to do the task properly and safely. The chiller oil should never be removed directly from the refrigeration system or from the high-pressure receiver. The best approach is to drain from an oil pot or oil sil, as this eliminates the risk of opening the system to the atmosphere.

Another way to improve efficiency is to perform an energy audit on your chilling system. The audit will make specific recommendations for your equipment and facility on how to lower energy usage. The energy audit looks specifically at the power usage of your system and compares its energy levels to an optimized system.

Regular maintenance is the best way to lower operating costs and prevent system failures. Some maintenance tasks should be done regularly, while some only have to be completed annually.

It’s also important to note that proper installation of your refrigeration system can significantly impact cost savings. The refrigeration system is more likely to work reliably and efficiently if it is installed and started up correctly.

Your compressor is crucial to operating your refrigeration system efficiently. While compressors are designed to run non-stop for years, the constant use can quickly wear on the compressors internal parts which can lead to a variety of issues.

You can optimize the life expectancy of your compressor by completing ongoing and annual maintenance tasks. If the compressor begins to malfunction, it may need to be replaced or overhauled to avoid dangerous conditions. In many cases, overhauling a compressor can be a less expensive way to update it.

Berg Chilling Systems has been working in the industry since 1972. Our experience and technical knowledge can help you increase your refrigeration system’s efficiency and decrease its operating costs. We can perform these five recommended tasks and provide recommendations on further ways your system can be optimized to improve its operational competitiveness. Contact us today to learn more and to request a quote for your facility.