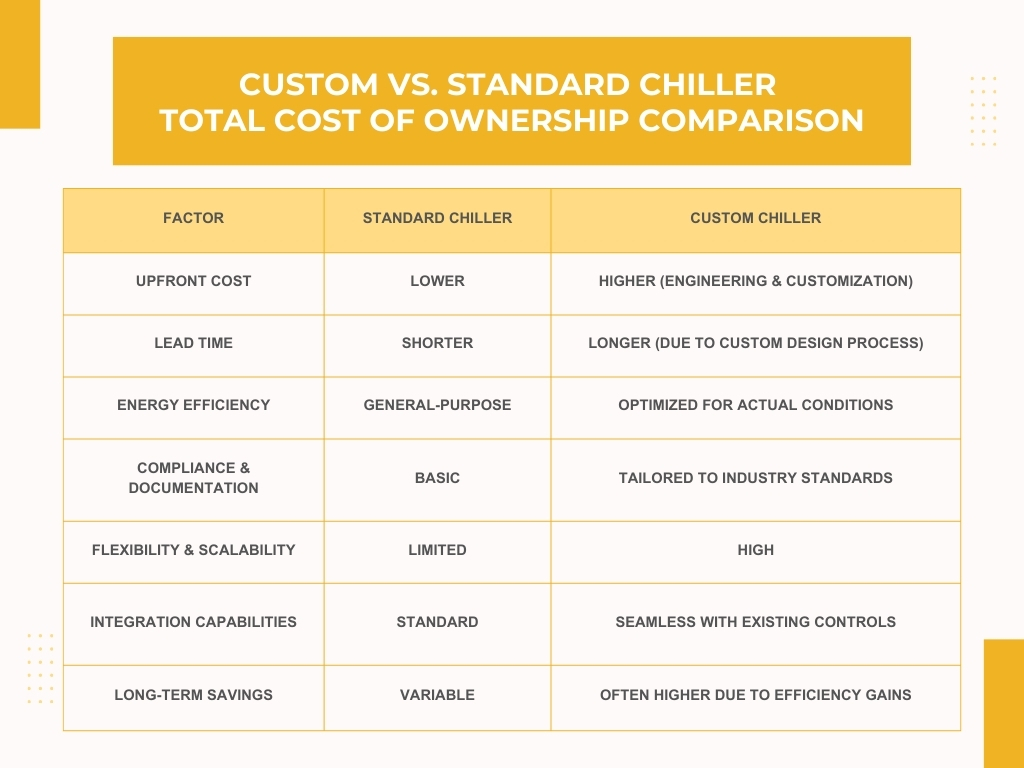

For industrial operations, an efficient and reliable cooling system is critical to maintaining product quality, equipment longevity, and energy efficiency. When selecting an air-cooled chiller, the choice often comes down to either a pre-engineered standard system with fixed capacities and configurations, or a custom-engineered solution designed to match your process conditions, site constraints, compliance requirements and performance expectations. While standard chillers can meet the needs of some industrial cooling applications, many industries require custom solutions to achieve optimal performance, regulatory compliance, and long-term cost savings. Understanding when a custom air-cooled chiller is necessary can have a significant impact on operating costs, uptime and reliability.

Standard industrial air-cooled chillers are pre-configured, off-the-shelf solutions designed for common cooling applications. They offer fixed capacities and configurations with limited customization, providing faster deployment and lower upfront cost for facilities with typical process cooling requirements.

You are looking for a quick and cost-effective cooling solutions with limited customization requirements, a standard air-cooled chiller may be a good choice for you.

Custom-engineered industrial air-cooled chillers are designed from the ground up to meet specific process, facility layout, environmental conditions, and performance goals. For facilities with specialized cooling demands, unique site constraints, or strict compliance needs, custom chillers can maximize efficiency, reduce operating costs, and improve long-term reliability.

Consider a custom air-cooled chiller if:

If your facility has complex process requirements, space constraints, environmental challenges, or regulatory mandates, then a custom-engineered air-cooled chiller can provide a tailored, high-performance solution with lasting value.

The right custom chiller doesn’t just solve immediate cooling challenges — it also future-proofs your operation by maximizing uptime, reducing energy costs, and ensuring regulatory compliance. To see how Berg’s custom engineering expertise has supported industries from plastics and food production to natural gas processing and pharmaceuticals, check out more of our Project Spotlights.

At Berg Chilling Systems, we specialize in custom-engineered air-cooled chillers for diverse industries — including food & beverage, plastics, pharmaceuticals, energy, and beyond. We work closely with clients to assess their unique process requirements and deliver tailored solutions that optimize performance, reliability, and lifecycle costs.

Contact us today to discuss your specific cooling challenges and discover how our custom-engineered solutions can improve your process efficiency.