Technical Specifications

Capacity

- Compressor (HP) 20 – 120 or more

- Cooling capacity (Refrigeration tons) 15 to 300 or more

Compressor Options

Semi Hermetic Compressor (WS)

- Semi-hermetic reciprocating compressor

- Suction gas cooled motor

- Suction and discharge stop valve

- Step capacity control

- Crankcase heater with current sensing relay

- Suction and discharge pressure transmitter

- High pressure switch

- Hot gas capacity control

Open Type Compressor (WO)

- Suction and discharge stop valve

- Step capacity control

- Drive coupling and C-flange adaptor/coupling guard

- Suction and discharge pressure transmitter

- Discharge high temperature cut-out

- High pressure switch

- Oil flow switch

- Oil separator with 230 V / Single phase / 50 Hz heater

- Oil heater current relay

- TEFC motor certified for hazardous environments

- Hot gas capacity control

Scroll Compressor (WZ)

- Suction gas cooled motor

- Suction and discharge stop valve

- High pressure switch

- Crankcase heater with current sensing relay

- Hot gas capacity control

Screw Compressor (WQ)

- Suction gas cooled motor

- Suction and discharge stop valve

- Slide valve capacity control

- Integral oil separator with heater and current sensing relay

- Crankcase heater with current sensing relay

- Suction and discharge pressure transmitter

- High pressure switch

- Hot gas capacity control

Evaporator

- High efficiency copper brazed stainless steel plate construction

- designed and constructed in accordance with ASME code

- High efficiency shell and tube construction

- Carbon steel shell (water side)

- Copper tube with inner fin (refrigerant side)

- Vessel designed and constructed in accordance with ASME code

*other materials of are construction available upon request

Water-Cooled Condenser

- Heavy construction while maintaining maximum heat transfer

- Steel shell on refrigerant side

- Copper tubing with outer fin on water side

- Removable heads for cleaning

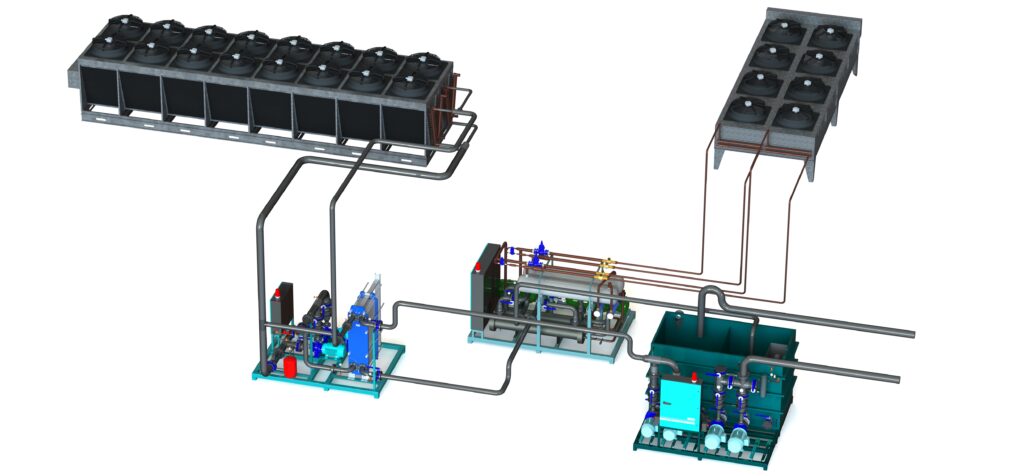

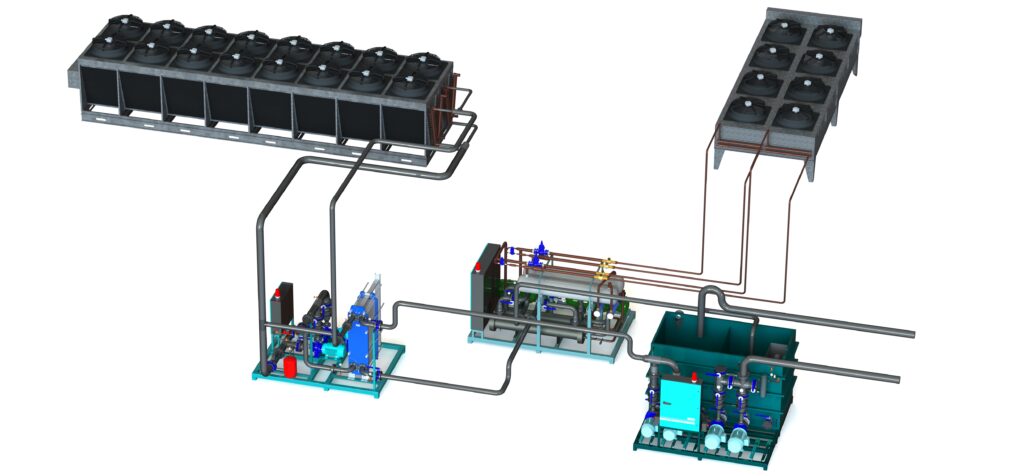

Stainless Steel Tank

- Baffled Stainless Steel type 304 Reservoir, 11 gauge

- Reinforcement bands

- Removable stainless steel cover

- Overflow connection

- Bottom drain connection with shut‑off valve

- Automatic float operated water make‑up valve

- Thermometer with well

- Spare well opening

- Closed cell flexible insulation nominal ½” thick applied to bottom and sides of tank

Centrifugal Pump Assembly

- Evaporator pumps circulate water from the hot well to the chiller and back to the cold well. This provides a constant flow and pressure for stable operation, maximum efficiency and safety.

- Process pumps circulate water from the cold well to the process and back to hot well. This flow may fluctuate without affecting the flow through the chiller.

- Optional combined standby pump, complete with valved header assembly is capable of acting as either the chiller or process pump if necessary to prevent any unnecessary shut-downs due to an operating pump fault.

- Dedicated standby also available

Pump assembly includes:

- Close coupled TEFC motor

- non-overloading impeller

- Cast iron volute

- Brass shaft sleeve

- Mechanical seal

- Suction shut‑off valve

- Discharge flow/shut‑off valve

- Discharge check valve

- Discharge pressure gauge

Reservoir Mixing Tank and Frame

- Frame manufactured from heavy gauge structured steel tube with welded construction.

- Tank models manufactured from heavy gauge stainless steel.

- Tank cover manufactured from stainless steel and supplied in sections for ease of removal and access ( Covers are optional ).

- All tanks have baffled compartments if required.

- Make-up float valve.

- Tanks are structurally supported around top and sides as required.

Fluid Cooler

- Available as either dry or adiabatic for added cooling capacity

- Heavy duty construction with maximum heat transfer

- Seamless copper tube mechanically expanded into the aluminium fins making permanent metal-to‑metal contact

- All galvanized construction for outdoor operation

- Self-contained controller for fan cycling to maintain set point.

- Coils are manufactured using seamless, deoxidized, heavy wall, smooth copper tubes

Electrical

- 460 / 575 / 230 / 380 Volts 60 / 50 Hz

- 120 / 240 Volt single phase control voltage

- Microprocessor controller

- Operating and fail lights

- UL or CSA approved components

Central Control Electrical Panel

A custom electrical control panel allows one point hookup and may include:

- HMI (Human Interface Device) touchscreens

- PLC (Programmable Logic Control)

- SCADA (Supervisory Control And Data Acquisition) communication systems

- 24/7 alarm reporting to beepers or cell phones

Safety Controls

Tested under load conditions prior to shipment

All safety controls are factory set and checked

- Freeze-up controls

- High and low refrigerant pressure controls

- Compressor motor overload protection

- Tank low-level cutout (glycol units)

- Oil pressure safety control

- Refrigerant pressure relief valve

All pump starters, fuses, disconnect, control voltage transformer, run and fail lights, are housed in a common NEMA rated panel.

Central Thermostat Control System

This system is used to control the chiller units in a multiple central chilling system. The temperature controller is located at the Berg tank and senses the process water temperature. The process water temperature is maintained by cycling the chiller units.