Berg’s rugged portable chillers are manufactured and factory tested under load conditions to ensure they stand the test of time. Our custom engineered portable refrigeration units for your unique application are developed for quiet operation, high efficiency and maximum return on investment.

Berg has packaged more high-performance and convenient features into our air and water cooled portable chillers. Plus, with our extensive list of available options, we can customize the portable chiller specific to your needs.

Best of all, we’ve kept our line of portable chillers remarkably affordable. Just choose the capacity that’s right for you, from 20 to 40 tons.

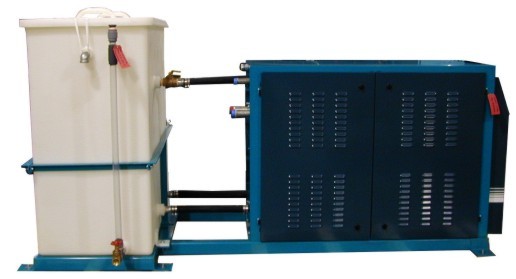

Portable chillers are particularly useful for small sized loads, special types of fluid and pressures, temporary use, and test applications. All of Berg’s portable refrigeration units come with a liquid chiller circuit and a pump tank system for a complete solution, and can also be configured to include a remote condenser. These pre-wired and pre-piped portable water chillers require minimum installation effort while occupying a small amount of floor space to save installation time and money.

Specification |

Water-Cooled Portable Chiller |

|---|---|

| Cooling Capacity (Refrigeration Tons) | 18.1 – 38.4 TR (R-513A) |

| Compressor (HP) | 20 – 40 HP |

| Refrigeration Circuits | Single and Dual Circuit Options |

| Reservoir | Large Stainless Steel |

| Pump Arrangement | Single, Dual, or 3-Pump Standby (Large Units) |

| Fluid Compatibility | Water, Glycol, and De-ionized Water |

| Pumping Pressure | 35 – 80 psi |

| Condenser Type | Brazed Plate-Type, Stainless Steel |

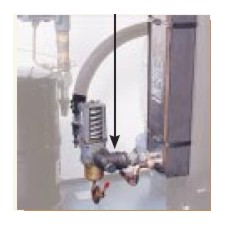

| Condenser Features | Includes Water Regulating Valve for flow control |

| Evaporator | Brazed Plate-Type, Stainless Steel |

| Compressor Type | Scroll Compressor with Gas-Cooled Motor |

| Compressor Features | Few Moving Parts, High Efficiency, Suction Service Valves |

| Electrical | 460 / 575 / 230 / 380 Volts, 60 / 50 Hz 120V Control Voltage, UL or CSA Approved |

| Controller | Microprocessor-Based, Character Display with Touch Buttons |

| Status Indicators | Operating and Fail Lights |

| Alarm Option | Rotary Red Beacon Light and Audio Alarm |

An optional third standby pump can be added to ensure the highest degree of reliability, compensate for environmental conditions and flexibility of maintenance.

An optional third standby pump can be added to ensure the highest degree of reliability, compensate for environmental conditions and flexibility of maintenance.

Berg engineers work with you to custom design the portable chiller that will meet your economic and functional needs.

Berg is available to you 24/7 for technical and service support.

All of Berg’s portable chillers come equipped with high system efficiency features.