In the dynamic world of industrial operations, heat pumps are instrumental in providing efficient heating and cooling solutions. These systems, which rely on a sophisticated mechanism to transfer heat between different sources, are central to various industrial applications. Understanding its operation is just the first step; ensuring its longevity and peak performance through regular and thorough maintenance is equally vital.

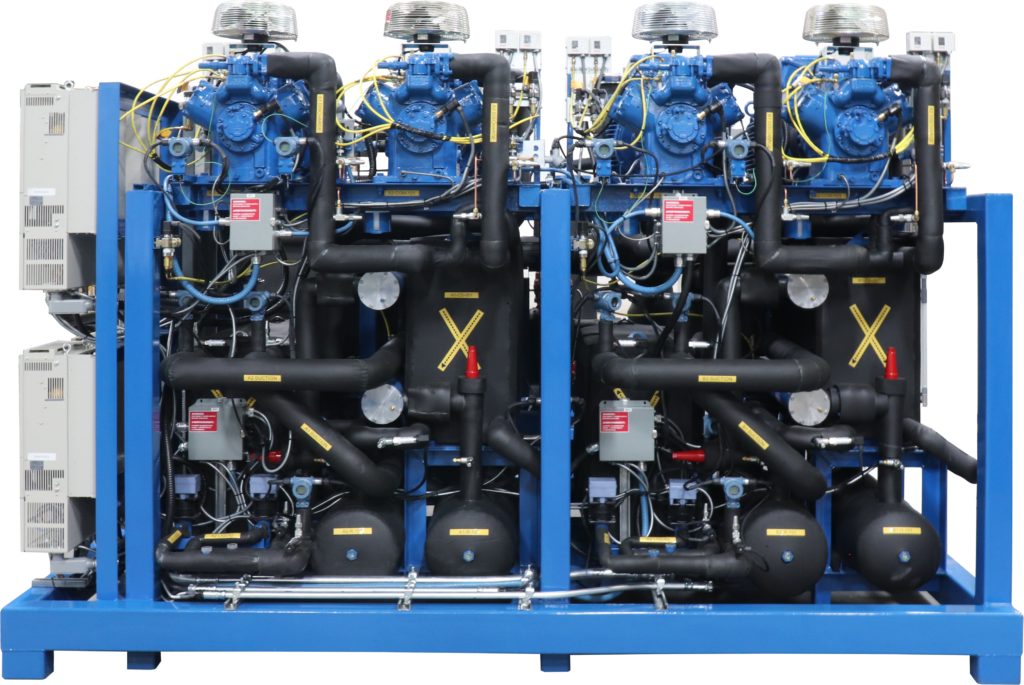

The first step in effective maintenance is understanding the type of heat pump you are working with. Industrial heat pumps come in various forms, each suited to different environmental conditions and operational needs. Key components such as the compressor, heat exchanger, expansion valve, and refrigerant are integral to the heat pump's functionality. Familiarity with this knowledge is essential for effective troubleshooting and maintenance.

Scheduled inspections and maintenance routines are essential for identifying potential issues early and preventing costly breakdowns. Regularly check the components, including the evaporator, compressor, condenser, expansion valve, and reversing valve, for any signs of wear, leaks, or malfunctions. Clean or replace air filters, coils, and fins as needed to maintain optimal airflow and heat transfer efficiency.

Proper refrigerant levels are critical for the efficient operation of a heat pump. Periodically monitor refrigerant levels and ensure they are within the manufacturer's recommended range. Low refrigerant levels can lead to reduced performance and increased energy consumption. If necessary, top up refrigerant levels or address any leaks promptly to prevent further damage.

Ensure that all moving parts, such as motors, fans, and bearings, are adequately lubricated to minimize friction and wear. Lubricate these components according to the manufacturer's recommendations to prolong their lifespan and maintain smooth operation.

Regularly calibrate the controls and settings of the heat pump to ensure accurate operation and optimal energy efficiency. Verify that temperature and pressure settings are calibrated correctly and adjust them as needed to suit changing operational requirements.

Keep the area surrounding the heat pump clean and free of debris, vegetation, or other obstructions that could impede airflow or cause damage to the system. Regularly remove leaves, dirt, and debris from outdoor coils and fins to maintain efficient heat transfer.

Consider implementing a preventive maintenance program tailored to your specific heat pump system and operational requirements. A proactive approach to maintenance can help minimize downtime, extend equipment lifespan, and maximize energy savings over the long term.

Regularly monitor performance metrics such as energy consumption, heating and cooling capacity, and operating temperatures to identify any deviations from expected norms. Analyzing these metrics can help detect potential issues early and guide optimization efforts.

Provide training and education for personnel responsible for operating and maintaining the industrial heat pump. Properly trained staff can recognize warning signs of potential problems, perform routine maintenance tasks effectively, and contribute to overall system reliability.

To maintain peak performance and reliability of your industrial heat pump, professional servicing and troubleshooting by qualified technicians are essential. These experts conduct comprehensive inspections to identify issues with components such as motors, fans, and refrigeration systems, providing accurate diagnostics and effective solutions. Whether it's repairing faulty connections or replacing worn-out parts, certified technicians ensure your heat pump operates reliably and efficiently. Additionally, they can help implement preventative maintenance plans tailored to your system, prolonging its lifespan and optimizing energy efficiency. By partnering with skilled professionals at Berg for professional servicing and troubleshooting, you ensure your industrial heat pump operates at its best, contributing to the success of your operations.

Safety should always be a priority. Always ensure that the power is disconnected before performing any maintenance tasks. Employing protective gear, like gloves and safety glasses, should be used during maintenance activities to prevent injuries.

By adhering to these maintenance practices and tips, you can significantly extend the efficiency and lifespan of your industrial heat pump. Regular maintenance not only reduces the risk of unexpected breakdowns and costly repairs but also ensures the smooth operation. For specific maintenance guidelines tailored to your heat pump model, consult the manufacturer’s manual. You may also consider professional training courses for a more in-depth understanding of heat pump maintenance and join online forums and communities for additional advice and shared experiences.

At Berg, we understand the essential role of heat pumps in the industrial landscape. We offer custom-engineered industrial heat pumping systems, developed in partnership with various sectors. Our systems are designed for diverse applications, including waste heat recovery and industrial process cooling, and comply with the highest safety standards. Choose Berg for innovative, tailored solutions and comprehensive service in industrial heating and cooling. Partner with us for efficient, sustainable industrial operations.

Contact us today to explore our services and discover how we can enhance your operational excellence with our advanced heat pumping systems.