Blown film extrusion is a highly intricate process, where controlling variables like air quality, temperature, and pressure are essential for producing consistent, high-quality films. In this process, even minor fluctuations in air quality can lead to defects, impacting the structural integrity and visual appeal of the final product. Berg’s Blown Film Coolers (BFCs) provide a solution by offering precise control over air quality, which plays a pivotal role in ensuring a stable film bubble, superior film quality, and efficient production.

At the core of blown film extrusion is the creation of a stable film bubble, which is inflated with air to shape the film and achieve the desired thickness and mechanical properties. The air quality within this bubble must be carefully controlled - impurities or inconsistencies in air temperature or pressure can lead to a loss of stability. Without precise air management, the bubble can collapse or develop weak spots, leading to costly disruptions and wasted materials. Through consistent airflow, precise control over air temperature, and regular filtration, manufacturers can stabilize the bubble and ensure smooth, even high-quality film production. This is especially important in achieving uniform film thickness, essential for applications like food and pharmaceutical packaging.

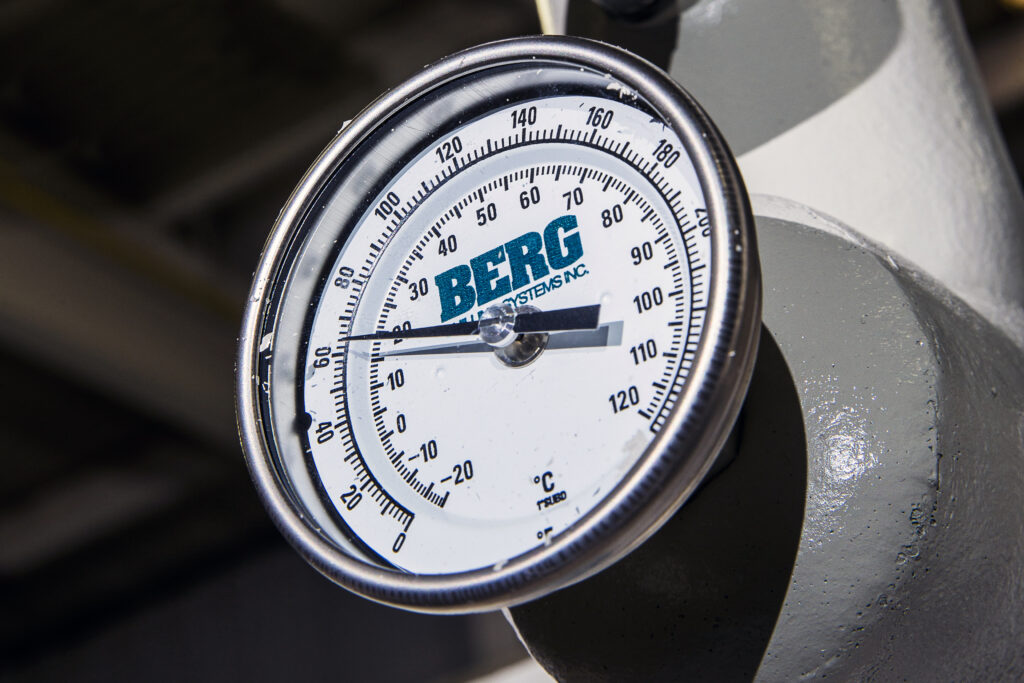

Temperature is another key element in the blown film extrusion process. The cooling air’s temperature directly influences how the film crystallizes as it cools, affecting properties like strength, clarity, and flexibility. If the air temperature fluctuates, it can lead to uneven crystallization, resulting in films with inconsistent thickness and quality. To avoid this, the cooling air needs to be precisely controlled to match the material’s specific thermal requirements. Consistent cooling allows for high-quality, uniform films that meet the strict requirements of industries relying on durable and flexible packaging solutions.

Contaminants like dust, oil mist, or water vapor can compromise film quality, especially in high-purity applications such as pharmaceutical packaging. These particles can embed within the film, creating weak spots and reducing both strength and clarity. High-efficiency air filters are essential for keeping the air entering the extrusion line clean, ensuring films meet stringent standards, maintain product integrity, and comply with industry regulations.

Berg’s Blown Film Coolers (BFCs) provide advanced air quality control with options tailored to specific needs. The standard BFC package includes inlet air filters, while custom features like mist elimination, condensate traps, blower inlet filters, and silencers offer enhanced purity for demanding applications. For the strictest requirements, ultra-pure HEPA filtration is available, delivering a comprehensive air management system critical for sensitive applications in food and pharmaceuticals.

The pressure of the air that forms the bubble is just as critical as temperature and purity. Variations in pressure can result in uneven bubble inflation, leading to non-uniform film thickness and surface inconsistencies. Precision control over air pressure ensures that the film bubble remains stable throughout the process, providing consistent film thickness and improved mechanical properties. By adjusting air pressure based on specific production needs, manufacturers can achieve uniform results, reducing the need for rework and minimizing material waste.

Maintaining precise air quality control not only improves film quality but also enhances operational efficiency. Contaminant-free air reduces the risk of production disruptions, while consistent temperature and pressure prevent material inconsistencies. This translates to less downtime, lower material waste, and improved productivity, all of which reduce overall production costs.

In blown film extrusion, every aspect of air quality control—from temperature and pressure to filtration—plays a significant role in the final product’s quality and consistency. For manufacturers, achieving precise air quality control is essential for maintaining competitive advantage, reducing waste, and meeting the high standards of demanding industries like food and pharmaceuticals. With the right approach to air management, the blown film extrusion process can deliver durable, high-performance films that meet industry expectations.

To meet the rigorous demands of air quality control in blown film extrusion, Berg’s custom-engineered BFCs provide precise temperature, pressure, and air quality management. Our BFCs are designed for all-season performance, integrating features like energy-efficient cooling, variable airflow control, and advanced filtration options. Built for durability and efficiency, Berg BFCs support manufacturers in achieving exceptional product quality and process stability. Contact us today to explore our tailored BFC solutions designed to confront your unique production challenges and elevate your manufacturing capabilities.