Industrial heat pumps offer an ingenious solution for energy efficiency, transforming low-temperature waste heat into high-value heat for various uses.

Industrial heat pumps offer an ingenious solution for energy efficiency, transforming low-temperature waste heat into high-value heat for various uses.

Typically, a substantial amount of heat is released from industrial refrigeration systems into the environment. Industrial heat pumps enable the reclamation of this heat for recovery purposes and reduce the consumption of fossil fuels for heating water. These innovations are not just eco-conscious but also cost-effective, empowering operators to fully leverage their energy assets, enhancing sustainability and economic performance.

Compared to the conventional refrigeration system, a heat pump produces hot water as the main output, and they offer both heating and cooling options. Industrial heat pumps can vary by source, whether it’s air, water or ground (geothermal). Whatever the type of heat pump system, Berg can provide you with the solution you need.

Our industrial heat pumps are customizable to your specific needs and are built in accordance with industry safety regulations and standards. They are available with standard HFC refrigerants and can be connected to a series of multiple heat pumps and chillers for more flexibility, reliability, and energy efficiency.

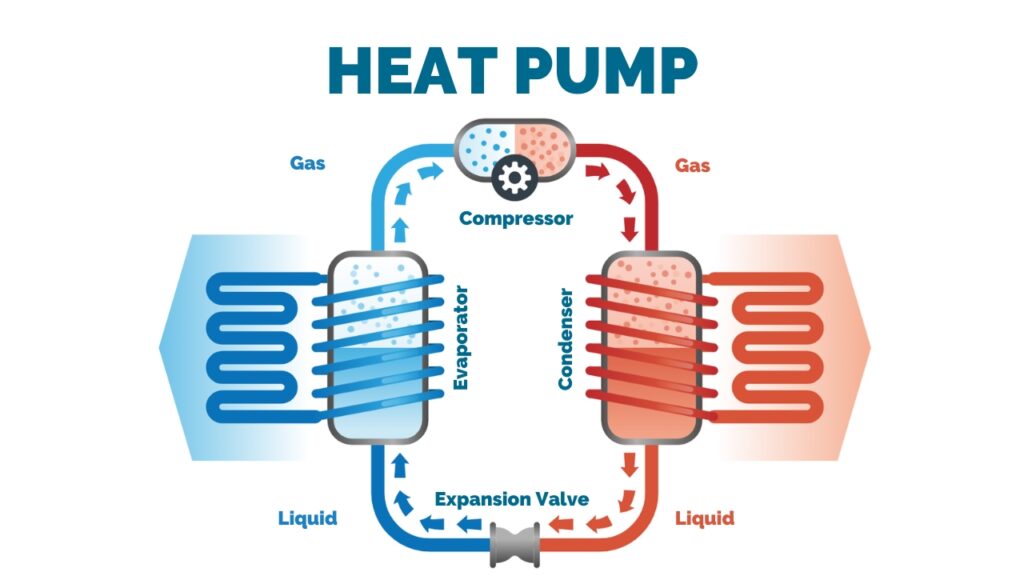

An industrial heat pump is a sophisticated system designed for the efficient transfer of thermal energy. It operates on the foundational principle of thermodynamics, moving heat from one location to another.

The system is engineered with four critical components: the evaporator, compressor, condenser, and expansion valve. The working fluid, known as the refrigerant, circulates through these components and is pivotal to the heat transfer process.

Evaporation: Within the heat pump, a specially formulated refrigerant, selected for its low boiling point, actively absorbs thermal energy from a heat source that is relatively low in temperature, such as ambient air, geothermal heat, or residual heat from industrial operations. This absorption causes the refrigerant to change from a liquid to a gaseous state.

Compression: Following evaporation, the now gaseous refrigerant is conveyed to a compressor, powered by either electrical or gas energy. The compression action escalates the pressure of the refrigerant, which in turn elevates its temperature significantly.

Condensation: The hot refrigerant enters the condenser. This is a heat exchanger where the refrigerant gives its heat to the heating system or an industrial process that requires it. As it loses heat, the refrigerant cools and returns to liquid form.

Expansion: Subsequently, the condensed high-pressure refrigerant is directed through an expansion valve. The pressure drop facilitated by the valve results in a decrease in temperature, restoring the refrigerant to its original low-temperature state.

Repetition: The refrigerant re-enters the evaporation phase, perpetuating the cycle to continue the heating process.

Utilizing latent environmental or waste energy sources and converting them into practical heat, industrial heat pumps represent an advanced energy-efficient solution that offers considerable energy savings and diminished carbon footprints, thus supporting worldwide ecological sustainability objectives.

Industrial heat pump systems are engineered to be adaptable, designed for diverse applications, capable of producing hot air, water, steam, and direct material heat. Whether it’s waste heat recovery or industrial process cooling, we offer complete flexibility in pumping assembly designs from dimensions to capacity, serving industries including:

Berg engineers work with you to custom design heat pump systems that will meet your economic and

functional needs.

Berg is available 24/7 for technical and service support.

All of Berg's systems come equipped with high system efficiency features

Over 50 years, Berg continues to work with companies in the various sectors for custom engineered industrial heat pumping systems.

Contact a Berg sales engineer today.